Refrigerated vans are an integral component of many businesses’ everyday processes. They allow for the safe and efficient transport of perishable goods across the country, sometimes from farms to the shop shelf. Industries such as dairy, pharmaceuticals and florists use refrigerated vans daily to spread their products across the UK. But how do they work? What allows stock to remain cooled at a constant controlled temperature whilst out on the road?

This blog will discuss the ‘behind the scenes’ of what makes refrigerated vans work and how they are powered, giving you all the details of the role refrigerated vans play in our everyday lives.

What is a refrigerated van?

Refrigerated vans are exactly what they say on the tin. They are vans used for transporting perishable goods, such as food, medicines or flowers, from point A to point B, whilst keeping them cooled at a constant optimal temperature. Various industries use refrigerated vans, including:

- Pharmaceutical

- Catering Suppliers

- Food Retailers and Supermarkets

- Scientific Research

- Hospitality

- Catering at Events/Festivals

- Fisheries and Seafood

- Seasonal Foods

- National Health Service

- Credit Hire Organisations

How do refrigerated vans work?

An easy way of explaining how refrigerated vans work is to compare them to your household fridge. They essentially work the same way, using insulated airtight containers that absorb heat whilst dissolving the outside heat, keeping the inside contents at a cool temperature.

The components that make up a refrigerated van can be broken down into three main parts:

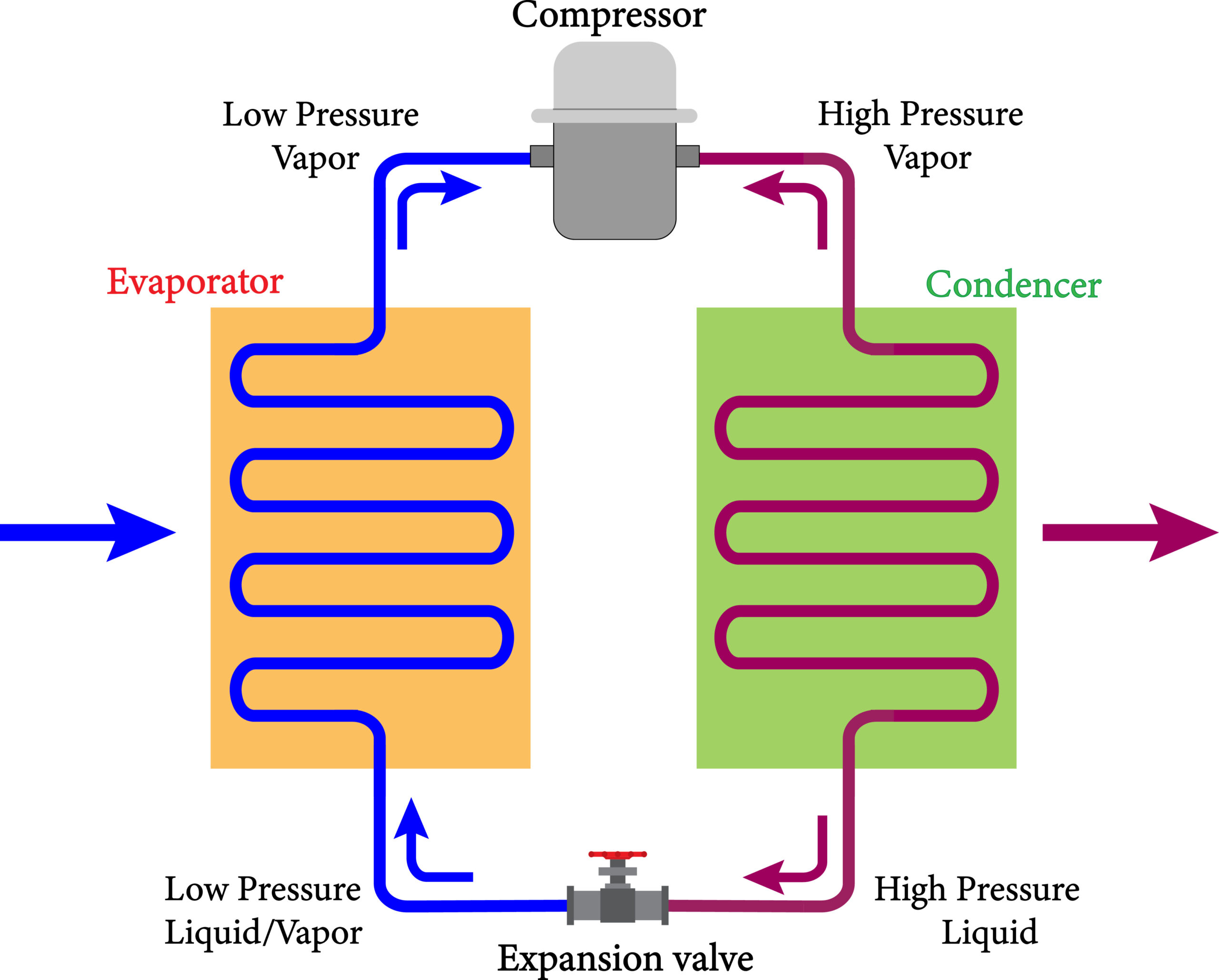

The Condenser

First, let’s look at the condenser. A condenser is designed to condense hot gas into a liquid. It is made up of a series of thin pipes, filled with a coolant fluid. A fan passes over the condenser, causing the hot gas from the compressor to condense into a liquid refrigerant. The heat then dissipates into the atmosphere so that the cooled liquid can pass to the evaporator.

The Evaporator

Next in the process comes the evaporator, a series of tubes that collects the refrigerant liquid. As the liquid enters, it begins to evaporate at very cold temperatures. Any remaining heat is absorbed. A fan then circulates cool air around the evaporator to reduce the temperature. The gas now created will exit the evaporator to enter the compressor.

The Compressor

Finally, the compressor accepts the gas from the evaporator and compresses it into a high-pressure gas, heating it to travel to the condenser for the cycle to repeat.

This process repeats constantly, working together to remove heat from the inside of the van. It keeps the internal temperature cool.

A refrigerated van does not set the temperature for the produce inside. Rather, whatever temperature the stock is upon being loaded into the van, the refrigerated van will work to maintain this temperature by removing unnecessary heat generated during the transportation. Once all the heat has dissipated, the cooling system will remain on standby until heat is generated once again.

How does heat enter the van? The answer is quite simple, through stock being stored with other stock that is higher in temperature than what is desired.

For example, if you are delivering frozen meats that are -10°C, while also transporting canned goods that are 5°C, the tinned goods will raise the temperature inside the van, meaning your frozen goods will no longer be kept at -10°C. This can be detrimental to your stock as storing frozen goods outside their optimal temperature can cause spoilage and foodborne pathogens to spread.

Another way heat can enter your refrigerated van is through the opening of doors, especially in warmer months. If you are delivering products over multiple drop-off points, opening the van doors will allow heat in, leaving your refrigeration unit a hefty job of removing it, until you next open the door. When making multiple deliveries, consider the placement of your goods inside the van. The first products to be delivered should be as close to the door as possible, to help minimise the amount of time the door is left open.

Insulation

An important component of a refrigerated van is its insulation. Commonly created from high-density polymer foam, insulation prevents heat from entering the van and keeps the cool air inside. Different refrigerated vans will utilise varying thicknesses of insulation, depending on the general temperature of goods it transports. A common thickness is 50mm, but for vans transporting frozen goods, 100mm is preferred.

How are refrigerated vans powered?

Now for all of this to work, there needs to be a source of power. We did say earlier that refrigerated vans are not too dissimilar to your household fridge. However, your fridge is powered through a mains supply; an impossible source for a moving van. So there must be another way.

Refrigerated vans are powered by their engine. A direct drive system with a compressor will be attached to the van’s engine, supplying it with power whilst on the road. The van engine can generate enough power to drive the vehicle, whilst also powering the refrigerated unit to keep your perishable goods cold.

In some cases, especially when a refrigerated van is expected to remain stationary for prolonged periods, a separate generator can be used to supply power.

Overall, refrigerated vans have an important part to play in the vital transportation of products all over the country, without which we would have limited access to foods, medicines and all other temperature-controlled products. Understanding the mechanisms behind refrigerated vans can be beneficial in diagnosing any problems you may encounter, or help you in the decision-making process for purchasing or renting your own refrigerated van. For some more information on how refrigerated vans can be of use to your business, read our guide The benefits refrigerated vans can have on your business.

Get your free quote today or visit our website to browse our available refrigerated vans.